Turbochargers are sensitive, thus they should be carefully handled. We follow all the typical steps of a thorough repair.

Our Services

Specialized methods of rebuilding the small damages of turbine blades can restore all damaged turbine in their original shape.

An out of balance rotating element causes operational difficulties, therefore a dynamic balancing is major for the efficient operation.

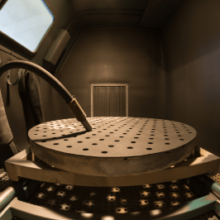

Sand blasting and glass bead blasting can be performed to every part of the turbocharger with our latest technology machineries.

Since the rotor shaft repair is a very important part of the turbocharger unit, we prioritize its repair providing dynamic gear

We have the expertise to recondition all the parts of a turbocharger, so as to reduce the cost of an overall replacement.

WHY CHOOSE US

1

2

3

4

5

5 REASONS TO CHOOSE TURBONAVE

Our Products

Turbochargers provides multiple advantages such as power increase, reduction of the fuel oil consumption and the thermal loading.

All bearings have passed the necessary quality control, so as to ensure perfect tolerance and operation.

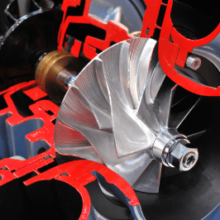

A turbocharger uses the waste energy of the engine’s exhaust stream to move the needed air with the help of a rotor.

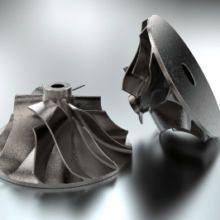

A compressor impeller is made of aluminum alloy or expensive titanium. The turbocharger’s operation affects the life of the impeller.

An overhauling kit contains all the necessary spare parts, for each turbocharger type.

Turbine blades are usually made of nickel chrome alloy or nimonic material, which has good resistance to creep, fatigue and corrosion.

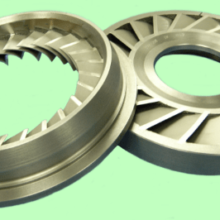

The nozzle ring is where the energy in the exhaust gas is converted into kinetic energy.

Upgrade your turbocharger with our Turbonave equipment.

We will be glad to respond to your needs.

Contact Us

Leave us your message

If you are interested in asking about our services or products, you are more than welcome. We will answer you as soon as possible.